Our client, a gold mine located in Mongolia, were experiencing leaking from their six Banlaw high flow nozzles and problems when filling their mining equipment. The issue was causing delays in filling, potential contamination and affecting their fuel management reconciliations.

We identified that the leaking was a result of the high wear environment and lack of regular servicing due to the mine’s remote location.

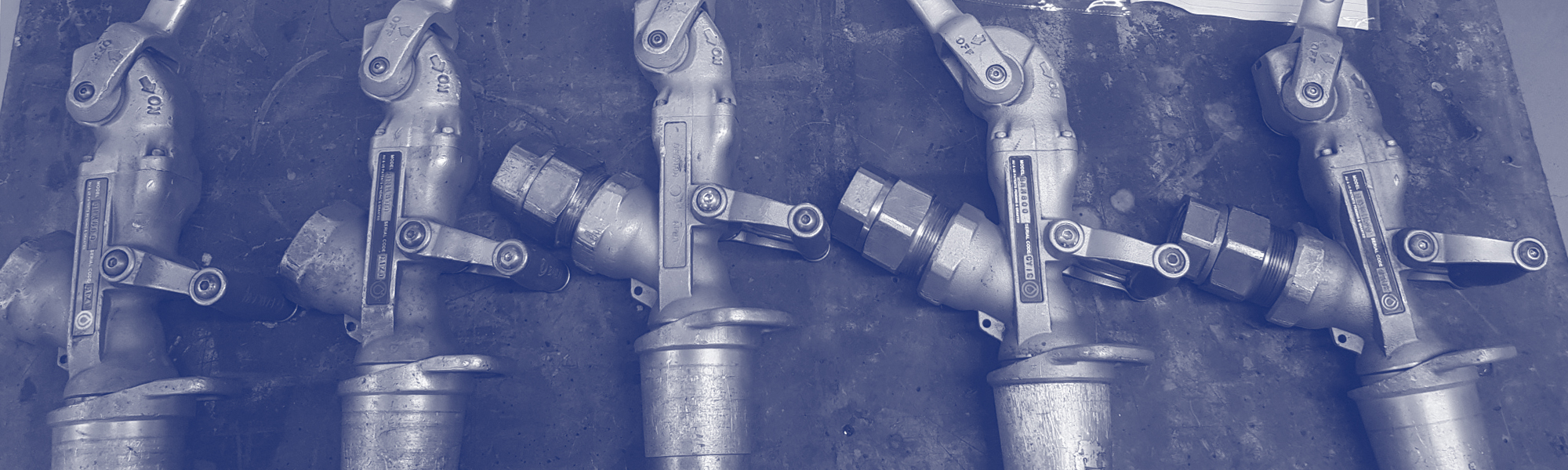

To solve the client’s needs we had the faulty nozzles sent to our Christchurch depot for testing and repair. At the same time we couriered a number of loan nozzles across the world to the mine, so they could continue their operations as usual.

We were able to repair the nozzles in a single day, achieving a fast turnaround thanks to our servicing experience and comprehensive supply of parts. The nozzles have since been returned to the mine and are operating as per specification with no further issues.

Petrotec is proud to be the only NZ distributor accredited to repair Banlaw nozzles.

Where

Gold mine in Mongolia

Duration

One day turnaround

Project team

Our in-house qualified and accredited Banlaw nozzle repairers